The solid tire rim is the rolling spare parts of transmission power and bearing the load by installed with solid tire to connect with the axle , Of the solid tires, only pneumatic solid tires have rims. Usually solid tire rims are as follows:

1. Split rim: a two-piece rim that fastens the tire by bolting under pressure. It is characterized by low price, little cumbersome installation, and inferior balance and stability to flat-bottomed rims. It is usually used on small-sized solid tires. Generally, solid tires below 15 inches use split rims. For example, the commonly used forklift solid tire is 7.00-12, the standard rim is 5.00S-12, and the split rim is used in most cases.

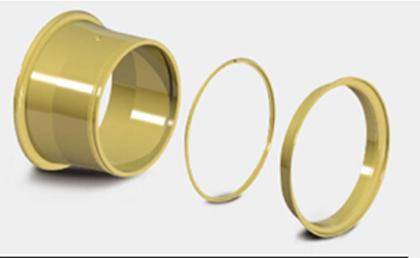

2. Flat-bottomed rim: This kind of rim has one or more pieces, which are characterized by good safety, stability and balance, but the price is little higher. In fact, all solid tires can use flat-bottomed rims, but considering the cost, they are usually used more on large-sized solid tires, especially the rims of solid tires above 15 inches are basically flat-bottomed. This kind of rim presses the solid tire onto the rim body by pressure, and then uses the side ring and the locking ring to fix the tire on the rim body, or use the solid tire itself to rib (nose) to fix the tire on the rim body, such as quick fit The quick-release rims used by the tires (Linde tires) are one-piece, without side ring and locking rings, and the tires are fixed through the nose of the tires into the grooves of the rim. Most of the flat-bottomed rims used in solid tires are two-piece or three-piece. In special cases, four-piece or five-piece rims are used. For example, 18.00-25 rims used in 13.00-25 tires are generally five-piece. .

Post time: 02-11-2022