Solid rubber tyres have become an essential solution for industries requiring maximum durability, puncture resistance, and stable performance under demanding conditions. As businesses seek safer and more reliable tyre options for forklifts, loaders, port equipment, AGVs, and construction machines, solid tyres offer long service life and consistent operational efficiency. For B2B buyers, understanding the advantages and application standards of solid rubber tyres is crucial for improving fleet productivity and reducing maintenance costs.

Why Solid Rubber Tyres Are Critical for Modern Industrial Operations

Solid rubber tyres are manufactured without an air cavity, eliminating the risk of punctures, blowouts, and pressure loss. Their robust design makes them ideal for heavy-load and high-frequency operations where downtime must be minimized. Unlike pneumatic tyres, solid tyres maintain structural integrity even in harsh environments with sharp debris, chemical exposure, or uneven surfaces.

As industries expand warehouse automation, logistics volume, and material-handling requirements, solid tyres support safer, more stable, and more predictable vehicle performance.

Key Advantages of Solid Rubber Tyres

-

Zero punctures and reduced downtime

-

Long wear life and stable running performance

These strengths make solid tyres especially valuable for high-intensity, 24-hour industrial operations.

Manufacturing Technology and Material Composition

Solid rubber tyres are produced using advanced compounding and molding technologies to ensure uniform density, heat resistance, and structural integrity. Many industrial tyres are manufactured in multi-layer designs, with each layer serving a specific function.

Typical construction may include:

-

Base Layer: Provides rigidity and ensures tight fitment on the rim.

-

Middle Cushion Layer: Improves shock absorption and reduces vibration.

-

Outer Wear Layer: Formulated with high-quality rubber compounds for abrasion resistance and long service life.

Reinforced bead structures, specialized tread patterns, and heat-dissipating sidewalls enhance overall performance while maintaining operator comfort during extended use.

Applications Across Warehousing, Ports, Construction, and Manufacturing

Solid rubber tyres are widely used in environments where safety, stability, and durability are more important than travel speed or suspension comfort. They excel in industries requiring repeated heavy lifting, tight maneuvering, or exposure to hazardous terrain.

Common applications include:

-

Forklifts, reach trucks, and pallet-handling equipment

-

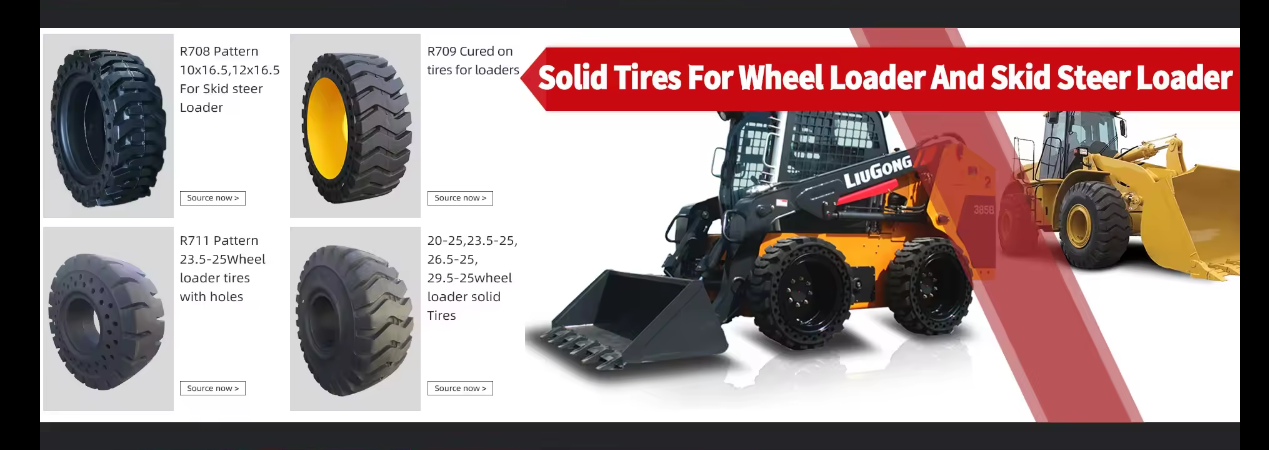

Telehandlers, skid-steer loaders, and compact construction machinery

-

Terminal tractors, port trailers, mobile cranes, and container handling machines

-

Automated guided vehicles (AGVs) and robotics platforms

Solid tyres perform reliably on surfaces contaminated with sharp metal scraps, broken glass, chemicals, or oil—conditions that would otherwise cause rapid damage to pneumatic tyres.

Performance Characteristics and Operational Benefits

Solid rubber tyres deliver consistent and predictable performance due to their rigid structure and wear-resistant compounds. Their advantages extend beyond simple puncture protection.

Enhanced Load Capacity

Solid tyres support heavier loads compared with pneumatic options, making them suitable for high-capacity lifting operations.

Reduced Maintenance Requirements

With no air pressure to monitor and no blowout risk, solid tyres significantly lower maintenance costs and eliminate unscheduled vehicle downtime.

Improved Safety and Stability

Their stable sidewalls reduce swaying and provide a firm footprint, improving safety in tight spaces and at elevated lifting heights.

Long Operational Life

Solid tyres typically offer two to three times the lifespan of pneumatic tyres, providing superior cost-efficiency in high-duty environments.

Choosing the Right Solid Rubber Tyres for Industrial Equipment

Selecting the correct solid tyre involves evaluating load capacity, operating conditions, tread pattern, and compound performance. For example, high-wear compounds are preferred for concrete floors, while deep-lug tread patterns are suitable for rough terrain.

Additional selection criteria include:

-

Tyre size and rim compatibility

-

Working speed and travel distance

-

Heat buildup and duty cycle

-

Indoor vs. outdoor application

-

Oil, chemical, or moisture exposure

B2B purchasers should assess these factors to match the tyre specification with their fleet operating requirements.

Trends in Solid Tyre Technology

Industry innovators are developing energy-efficient solid tyres with lower rolling resistance to reduce vehicle power consumption and extend battery life for electric forklifts. New-generation compounds enhance heat dissipation, enabling longer continuous operation. Increasingly, facilities are also adopting non-marking solid tyres for indoor use to prevent floor contamination.

Sustainability is another emerging focus. Recycled rubber blends and eco-friendly production processes are becoming more common as manufacturers aim to reduce environmental impact while maintaining performance standards.

Conclusion

Solid rubber tyres are indispensable for industries that require reliable performance, maximum durability, and minimal downtime. Their puncture-proof construction, long wear life, and high load capacity make them ideal for forklifts, construction equipment, port vehicles, and automated material-handling machinery. For B2B buyers, selecting high-quality solid tyres tailored to specific applications ensures safer operations, lower maintenance costs, and increased long-term productivity across the entire fleet.

FAQ

1. What is the main advantage of solid rubber tyres over pneumatic tyres?

They eliminate punctures and provide a significantly longer service life.

2. Are solid tyres suitable for outdoor rough terrain?

Yes, especially when using deep-lug or heavy-duty tread patterns designed for uneven surfaces.

3. Do solid tyres increase equipment stability?

Yes. Their rigid sidewalls reduce sway and improve load-handling safety.

4. Can solid tyres be used on electric forklifts?

Absolutely. Many solid tyres are specifically designed to reduce rolling resistance and extend battery life.

Post time: 20-11-2025