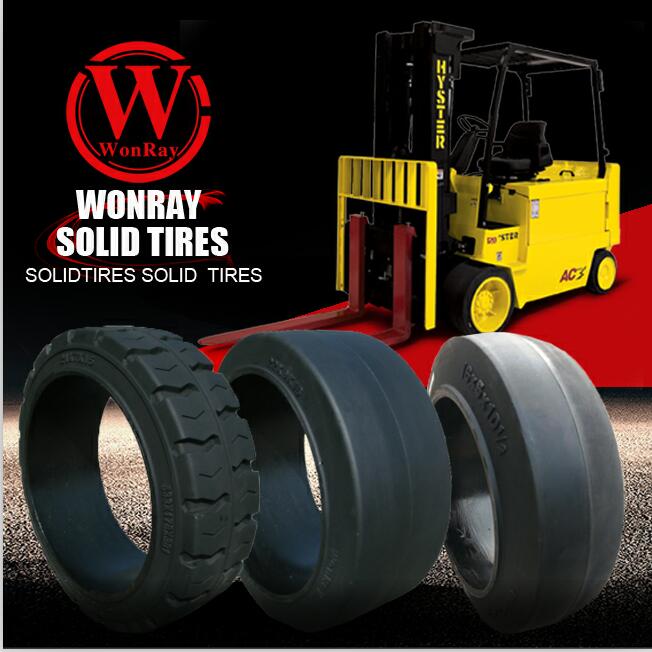

In the material-handling and logistics industry, solid forklift tires play a vital role in ensuring safety, stability, and efficiency. The 16 x 6 x 10 ½ model, commonly used as a rear tire size, delivers excellent load-bearing capacity, puncture resistance, and long service life—qualities that are essential for high-intensity warehouse and industrial operations.

Why Solid Tires Are Essential for Forklift Operations

Unlike pneumatic tires, solid tires are made entirely of rubber, eliminating the risk of flats and downtime. For businesses that rely on consistent forklift operation, they offer significant advantages:

-

No Air Leaks or Blowouts – Zero maintenance from punctures.

-

Exceptional Durability – Withstands wear, cuts, and abrasions.

-

Enhanced Stability – Ensures firm traction on various surfaces.

-

Cost Efficiency – Longer lifespan means reduced replacement frequency.

These traits make solid tires the preferred choice in warehouses, factories, ports, and logistics centers.

Key Features of Solid Tires 16 X 6 X 10 ½

This specific size provides a balance between grip, comfort, and operational strength — ideal for both indoor and outdoor use.

Main Specifications

-

Size: 16 x 6 x 10 ½ (commonly used as a rear tire)

-

Material: High-performance solid rubber compound

-

Load Capacity: Excellent weight distribution under heavy loads

-

Tread Pattern: Deep grooves for improved traction

-

Temperature Resistance: Designed to endure varied industrial environments

Operational Benefits

-

Reduced rolling resistance for better energy efficiency

-

Improved ride comfort with less vibration

-

Compatible with both electric and diesel forklifts

-

Suitable for a wide range of industrial wheel rims

Industrial Applications

Solid forklift tires of this size are widely used in:

-

Warehouses & Distribution Hubs – For smooth, flat surfaces

-

Ports & Terminals – To withstand rugged or wet terrains

-

Manufacturing Plants – For areas with metal debris or sharp objects

-

Construction Sites – Where tire puncture resistance is crucial

Choosing the Right Solid Tire

When selecting a solid tire, businesses should consider:

-

The forklift manufacturer’s recommended tire size.

-

The working environment (indoor, outdoor, or hybrid).

-

The frequency and intensity of operations.

-

The reliability and reputation of the tire brand.

Conclusion

The Solid Tires For Forklift 16 x 6 x 10 ½ model offers exceptional durability and reliability, making it a cost-effective solution for demanding operations. Its puncture-proof structure, strong load capacity, and minimal maintenance requirements help companies improve forklift performance, reduce downtime, and enhance operational safety.

FAQ

1. What forklifts can use 16 x 6 x 10 ½ solid tires?

They fit most standard counterbalanced forklifts, especially for rear wheels of electric models from major brands like Toyota, Hyster, and Mitsubishi.

2. How long do solid forklift tires last?

On average, they last two to three times longer than pneumatic tires, depending on usage conditions.

3. Are these tires suitable for outdoor environments?

Yes, solid tires with deep tread patterns perform well on both indoor floors and outdoor surfaces like concrete or asphalt.

4. Can I replace pneumatic tires with solid ones directly?

Usually yes, but you should confirm compatibility with your forklift’s rim type and size before installation.

Post time: 28-10-2025